START YOUR SMART ENERGY FUTURE TODAY

THE BENEFITS OF GOING SOLAR

There is a quiet solar revolution happening on the rooftops of India. At Sunrise Solar we are proud to be leading the change, one home, one family, one solar panel at a time. We are helping smart India make a real difference to the planet, cutting electricity bills, and connecting them to their smart energy future. It’s time to join the revolution.

QUICK CONTACT

Evacuated Tube Collectors (ETC) Solar Water Heater

The Evacuated Tube Collectors (ETC) series of solar water heaters are the most efficient ones, they are built to work seamlessly all through the year, the all-weather solar water heaters function effectively to deliver piping hot water to the entire family.

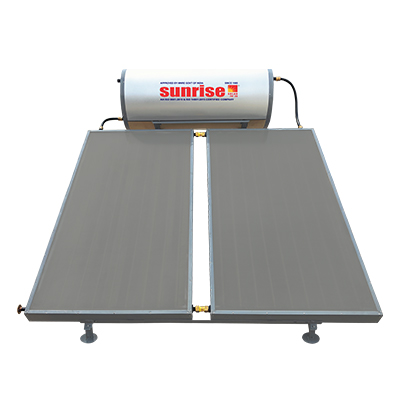

Flat Plate Collectors (FPC) Solar Water Heater

The FPC Solar Water Heaters are highly efficient due to their technology, the copper plates absorb maximum solar power to deliver the necessary hot water for the whole family.

Evacuated Tube Collectors (ETC) Solar Water Heater

The Evacuated Tube Collectors (ETC) series of solar water heaters are the most efficient ones, they are built to work seamlessly all through the year, the all-weather solar water heaters function effectively to deliver piping hot water to the entire family.

Flat Plate Collectors (FPC) Solar Water Heater

The FPC Solar Water Heaters are highly efficient due to their technology, the copper plates absorb maximum solar power to deliver the necessary hot water for the whole family.

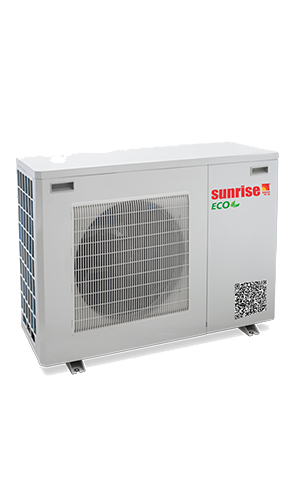

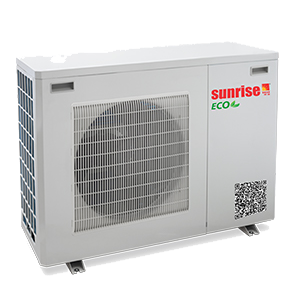

Sunrise Heat Pumps

Heat pumps use a refrigerant as an intermediate fluid to absorb heat where it vaporizes, in the evaporator, and then to release heat where the refrigerant condenses, in the condenser.

Solar Rooftops Systems

Solar rooftops are solar panels placed on top of roofs of residential, commercial, institutional, or high-rise buildings. They capture the light energy emitted by the sun and convert it into electrical energy. This is known as a solar rooftop system.

Sunrise Heat Pumps

Heat pumps use a refrigerant as an intermediate fluid to absorb heat where it vaporizes, in the evaporator, and then to release heat where the refrigerant condenses, in the condenser.

Solar Rooftops Systems

Solar rooftops are solar panels placed on top of roofs of residential, commercial, institutional, or high-rise buildings. They capture the light energy emitted by the sun and convert it into electrical energy. This is known as a solar rooftop system.

PRODUCTS

Popular Cities

- EVERY CARBON FOOTPRINT COUNTS

- SOLAR POWER SUSTAINS LIFE & SAVE ELECTRICITY

- QUALITY PRODUCTS LIFESPAN & ITS UTILITY

- CUSTOMER SATISFACTION & HAPPINESS

Every carbon footprint counts

Erase your carbon footprint by opting for a solar water heater

Every individual should contribute to his best abilities to make the world liveable; the concern of the ecology and its related issues is a worrying matter for all people living on the planet.

Solar power sustains life

An Electric Geyser consumes over 180 kWh per month.

Switch over to a solar water heater and save electricity and money.

Opting for a solar water heater can help every family save electricity and money, going solar is the most effective and sustainable method for people on planet earth.

Turn towards sustainable solar power and thrive life on earth.

Quality is the measure of a products lifespan and its utility

Sunrise Solar products lasts long and serve long, the superior manufacturing quality serves you for a lifetime.

Sunrise solar products are built with world-class superior technology; the company is the second company in India to obtain the Bureau of Indian Standards certification. The company has relentlessly strived to achieve superior product standards in every solar product manufactured at their facility for the past 3 decades.

Great service is the direct measure of customer satisfaction and happiness

Sunrise Solar products unquestionably deliver great service to all its customers with its superior solar technology.

Sunrise solar products by virtue of being built on a superior technological foundation last long and serves greatly, the customer’s satisfaction levels are boundless and make them extremely happy.

SOLAR INSTALLATION PROCESS

Sunrise Solar has a team of well-trained engineers to install the Solar Water Heaters. The Solar Water Heaters comprise heavy boilers, support lines, solar panels, and a host of other accessories. The installation should be executed in a methodic manner; the process is quite complicated and needs utmost attention.

Step 1 – Enquiry

Just inquiry by Phone or Email. We are happy to help you.

Step 2 – Site Inspection

Our team will inspect your site free of cost.

Step 3 – Proposal

A detailed commercial offer will be presented to you via email.

Step 4 – Approval process

Order confirmation approval is required.

Step 5 – Installation

Our professional team will install it at your site location.

Step 6 – Maintenance

Required maintenance of the product.

TOP SOLAR COMPANY IN INDIA

Sunrise Solar has ventured into the manufacturing of solar water heaters with comprehensive and thorough know-how on the technology, every Sunrise Solar water heater product is a near-perfect product with absolutely zero technical glitches. The result of a perfect product is the overall discipline and process that has been deployed in the manufacturing process.

Sunrise Solar is nearly a 3-decades old company; the company has gained excellent experience in the last 3-decades of its inception by manufacturing and installing lakhs of solar water heaters across thousands of Indian residences.

REASONS TO CHOOSE SUNRISE SOLAR PRODUCTS

Solar energy is abundant and eternal

Tapping energy that is abundant in its supply and expanse could be the smartest step that mankind can endeavor, sourcing energy for the future of mankind should be on top of the agenda. There is already a severe energy crisis that is looming large in the present, the future could be worse if it is not addressed, hence sustainable and renewable energy formats need to be sourced for the preservation and sustenance of life. The most effective and efficient form of sustainable energy is solar energy, solar energy is available in abundance, and utilization of the same is the need of the hour.

The future world will be largely dependent on renewable and sustainable energy; solar energy will lead the energy quest from the front. The other energy formats aren’t as popular as solar energy and deployment and utility of the same is rather impractical.

World-class and energy-efficient solar products deck Sunrise Solars Portfolio.

By virtue of being a pioneer in the solar industry, Sunrise Solar has initiated many pioneering and breakthrough innovations to develop some finest and highly effective solar products.

Sunrise Solar has over three decades of experience and expertise in the industry, the company is one of the top solar water heater manufacturers from Bangalore and their reputation stretches through India and Asia.

By consistently initiating innovation on various aspects in the development of solar water heaters, the company has gained superiority in all the product ranges it manufactures.

World-class and energy-efficient solar products deck Sunrise Solars’ portfolio

By virtue of being a pioneer in the solar industry, Sunrise Solar has initiated many pioneering and breakthrough innovations to develop some finest and highly effective solar products.

Sunrise Solar has over three decades of experience and expertise in the industry, the company is one of the top solar water heater manufacturers from Bangalore and their reputation stretches through India and Asia.

By consistently initiating innovation on various aspects in the development of solar water heaters, the company has gained superiority in all the product ranges it manufactures.

Solar Water Heaters – Leading the initiative in energy sustenance

Solar Water Heaters lead the initiative in saving electricity and in the endeavor of utilizing natural energies; the installation of the appliance in every household can reduce dependence on hydroelectricity to a large extent and save hydroelectricity.

Solar Water Heaters are one of the most significant contributors to climate change and electricity, installing and deploying efficient solar water heaters should be the topmost priority for everybody.

Superior product range combined with long-lasting service

Sunrise Solar products are not just energy-efficient appliances; they are also powered to sustain rigorous outdoor and tough climatic conditions, the solar water heaters are strongly built to serve a long period without any technical glitches. The solar water heaters efficiently address all apprehensions of today’s consumers and deliver on high value and durability.

Superior product range combined with long-lasting service

Sunrise Solar products are not just energy-efficient appliances; they are also powered to sustain rigorous outdoor and tough climatic conditions, the solar water heaters are strongly built to serve a long period without any technical glitches. The solar water heaters efficiently address all apprehensions of today’s consumers and deliver on high value and durability.

INDIA'S LEADING SOLAR PRODUCTS MANUFACTURING COMPANY

SUNRISE SOLAR BRAND

CERTIFIED APPROVALS

UNITS SOLD

BRANCHES

CHANNEL PARTNERS

CLIENTS

TESTIMONIALS

Installed in 1989 and is giving excellent service even after 29 years of daily use.

The best quality is using the last 17 years without any kind of maintenance, Thank you sunrise.

Best quality ever. On-time service Thank you, sunrise Team.